Tires might look simple from the outside, but inside they’re a complex mix of dozens of compounds designed for strength, safety, and performance. Now, Continental is reshaping that formula with an eye toward sustainability by turning waste streams such as used cooking oil into synthetic rubber for its next generation of tires.

Raising the Bar on Sustainability

Continental has made renewable and recycled materials a cornerstone of its production strategy. In 2024, roughly 26 percent of the materials used in its tires were sustainable. That figure is expected to climb by another two to three percentage points this year, with a longer-term target of at least 40 percent by 2030.

“We’re closing the loop: Continental is ramping up its commitment to a circular economy and mapping out its path for the future,” said Jorge Almeida, Head of Sustainability at Continental Tires. “Innovative solutions enable us to use more sustainable raw materials, such as synthetic rubber made from used cooking oil or resins based on certified renewable feedstocks.”

Why Rubber Matters

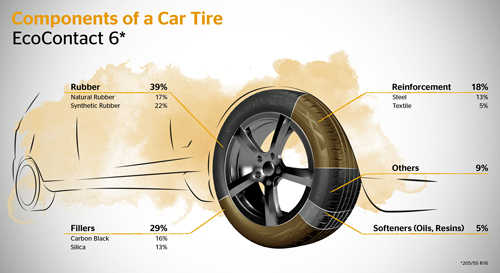

Rubber is one of the most critical ingredients in tire manufacturing, accounting for up to 40 per cent of a tire’s weight. A single tire can incorporate as many as 100 raw materials, blended into 20 or more specialized rubber compounds depending on its intended performance.

Natural rubber, prized for its durability and resistance, remains essential for treads on cars and trucks. Its unique properties, such as strain-induced crystallization, still cannot be fully replicated in a lab. Synthetic rubber, however, has its own advantages, offering improved braking performance and reduced rolling resistance. By incorporating sustainable synthetic rubber sourced from waste oils, Continental aims to combine performance with a reduced environmental footprint.

Cooking Oil to Road Grip

One of the most innovative steps comes from sourcing synthetic rubber from pyrolysis oil made from end-of-life tires and from recycled cooking oil. Working with suppliers such as Synthos and TotalEnergies Cray Valley, Continental applies a mass balance approach to ensure these sustainable inputs are accurately tracked and certified under the ISCC PLUS International Sustainability and Carbon Certification program.

That means the same fries oil that once sizzled in a deep fryer could eventually help keep a car safe on wet roads.

Circular Resins Improve Performance

Beyond rubber, Continental is also focused on resins, the compounds that fine-tune the elasticity and resilience of tires. These resins directly influence grip, rolling resistance, and wear resistance, which in turn affect fuel economy and EV range. By sourcing circular resins made from renewable or recycled feedstocks, Continental not only maintains high performance standards but also reduces dependency on fossil-based raw materials.

Lower-Carbon Additives

Additives, though small in volume, play a big role in tire production. Continental has become the first tire manufacturer to use ISCC PLUS-certified TMQ, an antioxidant additive developed by LANXESS. Produced using biocircular acetone sourced from biological waste streams such as cooking oil, the additive reduces carbon footprint by more than 30 percent compared to its conventional counterpart.

Tracking Progress

Central to all of these initiatives is the mass balance method, which blends fossil, renewable, and recycled inputs during production but ensures traceability across the supply chain. Matthias Haufe, Head of Material Development and Industrialization at Continental Tires, explained:

“The mass balance approach enables us to efficiently manage the complexity of the raw materials portfolio and track how these raw materials are used at multiple production sites in a wide range of markets. In this way, we can steadily increase the share of renewable and recycled materials in our tire production, and transparently document the progress we make.”

A Roadmap to 2030 and Beyond

For Continental, the journey is both technical and strategic. Achieving 40 percent renewable and recycled content by 2030 requires rethinking not just rubber but the full spectrum of materials, resins, additives, and supplementary compounds that make up a modern tire.

By turning everyday waste like cooking oil into high-performance rubber, Continental is proving that sustainability and mobility can roll together. And with global demand for tires only expected to grow, innovations like these are helping chart a more responsible future for the industry.