Making the automotive engine more efficient is the goal of many automotive aficionado’s, whether they be building a race car, working as an engineer on a new engine design or an everyday driver hoping to get more power and better fuel economy. While people who build cars can change design to create more efficiency, we as consumers are limited to more simple things like maintaining tire pressures, getting wheel alignments, having tune-ups and utilizing more economical driving patterns. However, if you are looking to maximize your engine’s efficiency and considering the purchase of a newer vehicle, then one of the items on your check list should be getting an engine that incorporates variable camshaft timing.

Camshafts could be thought of as the “personality” of the engine. Choosing a camshaft with different lobe profiles (lobe design determines when and how high the engine valves open) can make the engine a smooth idling economy powerplant with limited horsepower but good low rpm torque, or it can change it into a lumpy idling unit that only develops power at high rpm. Until the variable camshaft designs were incorporated, drivers were limited to either smooth idle or max power and most camshafts were a compromise between these two. Variable camshaft timing gives us the benefits at low and high rpm.

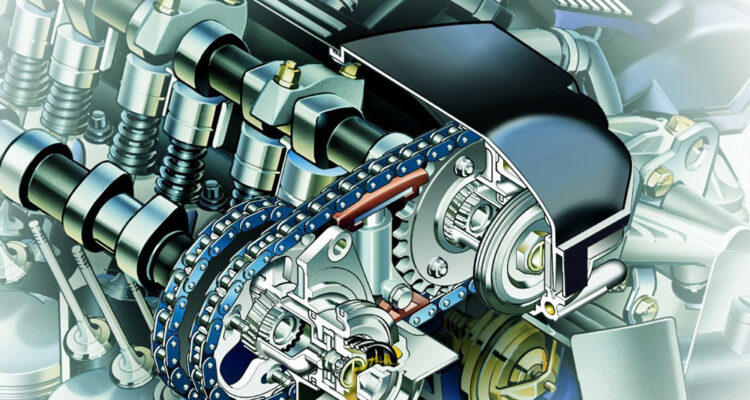

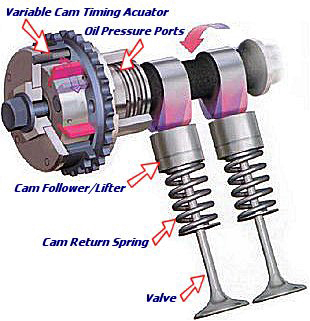

To vary the camshaft timing, a typical design uses a hydraulically operated mechanical mechanism located as part of the timing gear or sprocket bolted to the front of the camshaft. The engine computer controls oil flow through and electric solenoid and this oil flow will move the rotation of the camshaft back and forth in relation to the sprocket. The Sprocket is driven, most often by a chain from the crankshaft to turn the camshaft and open the valves.

There are several variations of the variable camshaft mechanical mechanism. Many use oil pressure acting against vanes or paddles inside a housing to change the angle of the sprocket in relation to the camshaft. Others are using a helical gear (the teeth are at an angle) inside the sprocket and changing the position in or out of the sleeve over the helical gear changes the cam timing. I sometimes compare this to looking at a nut and bolt. Turn the nut on the threads and it moves in and out. If you could simply force the nut in and out, it would cause the bolt to rotate, and that is exactly what the camshaft does to change the timing.

It is possible for many types of variable camshaft timing mechanisms to rapidly “bounce” back and forth till oil pressure develops during start-up. This can create a knocking sound, so many designs incorporate a spring-loaded “locking” pin that prevents the variable camshaft timing from changing. Once oil pressure develops, the locking pin releases and the variable camshaft timing can begin. Sludge or dirty oil can prevent the Locking pin from operating. Clean oil is a must for these systems.

So how does the variable camshaft timing improve efficiency? Simply put, it allows the most air into the engine regardless of the engine rpm. By advancing the camshaft and opening the valves sooner, you allow more air into the engine at low rpm and the valve closes sooner so more pressure is made in the engine cylinder during the compression stroke. More cylinder pressure equals more power.

However, at high rpm, it is better to hold the valves open longer to allow the inertia of the fast moving air to help force more air into the cylinder. Retarding the camshaft timing keeps the valves open later in the engine cycle. During operation, the camshaft timing will be varied to meet the driving conditions. For example, during deceleration and some cruise conditions, the exhaust valves will be closed sooner to keep waste exhaust gases in the cylinder. This has the same effect as the EGR (exhaust gas recirculation) systems had, keeping inert gases in the cylinder to lower cylinder temperatures and reduce exhaust emissions. On some turbocharged engines, the intake valve may be kept open later to reduce the cylinder pressure on the compression stroke during cruise conditions. This lowers the “pumping losses” which make the engine more efficient.

Some designs have variable cam timing on just the exhaust but many have it on both the intake and exhaust valve trains. Both are better, but costlier. They do make your engine much more efficient.